The Risks of LED tubes with integral driver

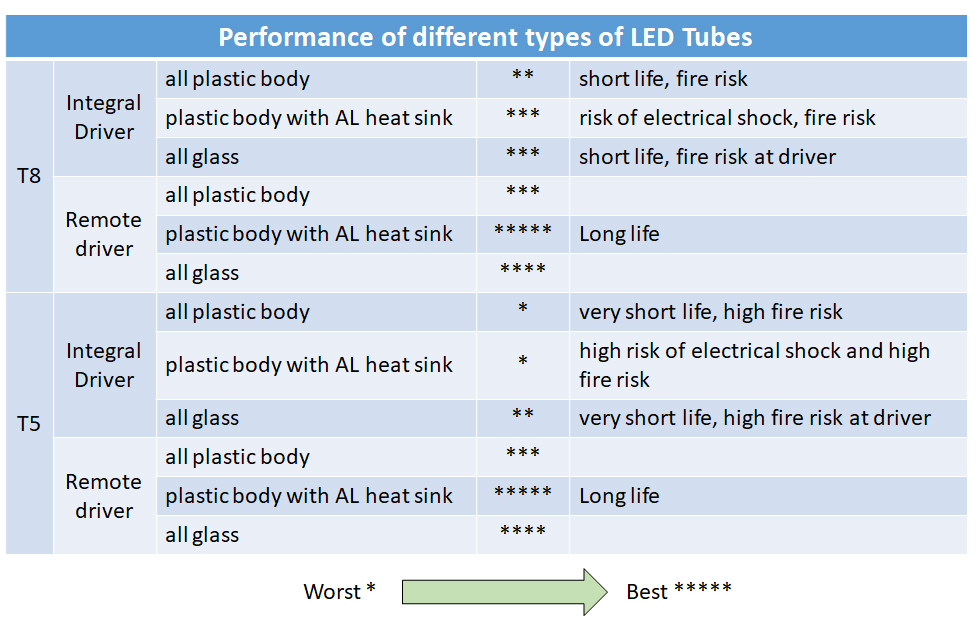

Tube Design

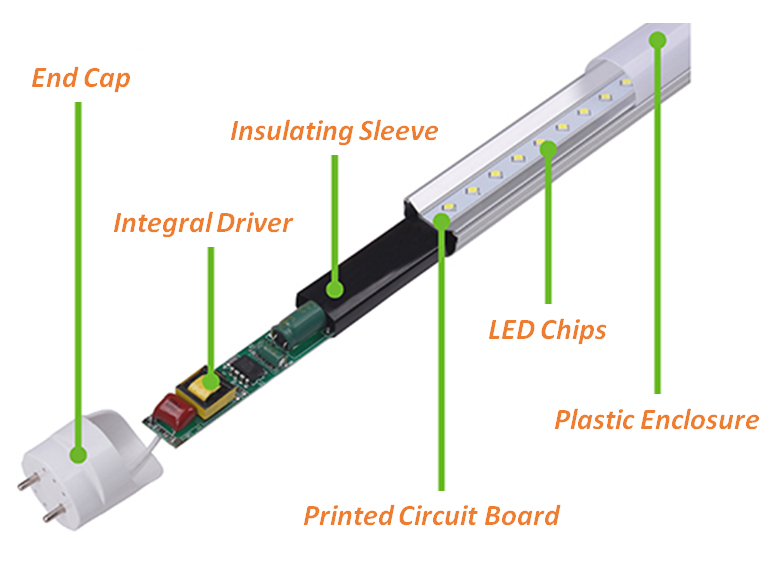

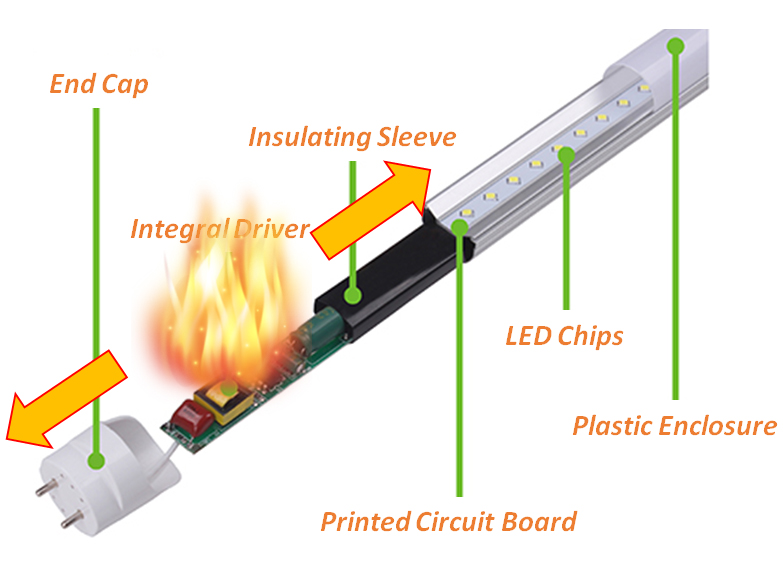

Most LED tubes in the market are of integral driver type. They consist of 1) a printed circuit board (PCB) with LED chips mounted on it and 2) a driver at one end of the tube. The body of the tube can be of plastic (normally polycarbonate) or glass. In both cases, the driver is housed in the end cap (normally not polycarbonate)

With the small space available, the electronic circuitry of the driver can only be arranged by 1) sacrificing heat dissipation ability and 2) using underrated components especially the electrolytic capacitors.

Fire Risk

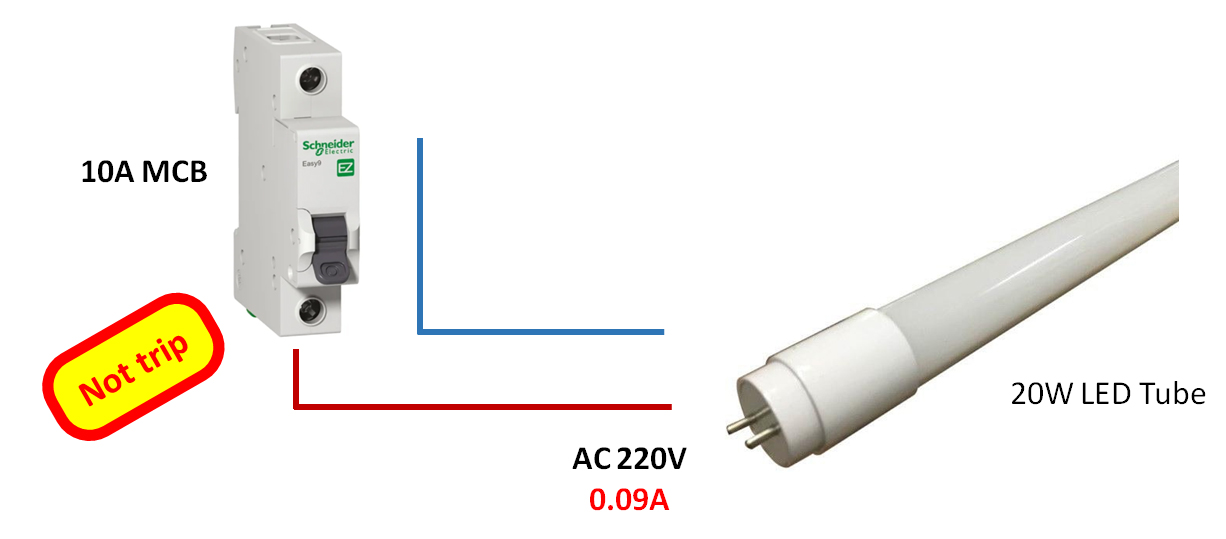

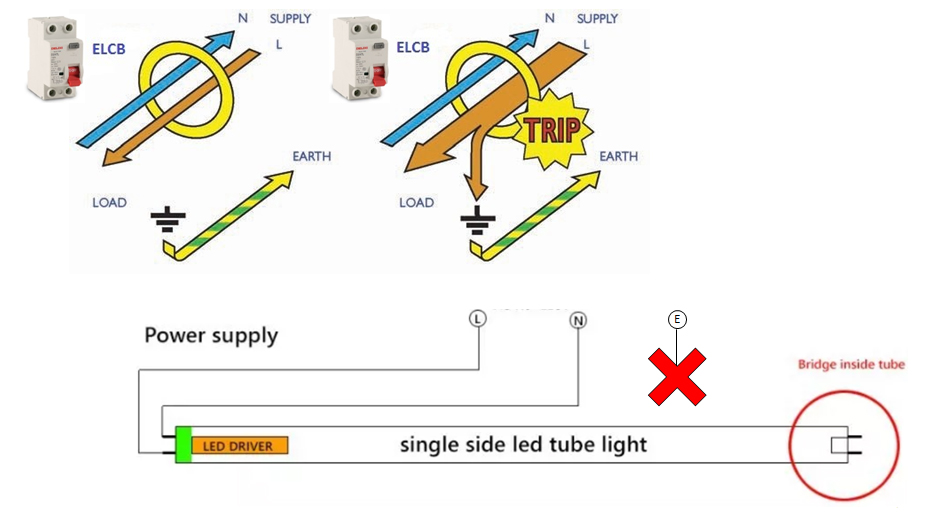

Highest risk of poorly designed LED tube is the overheating of combustible materials such as paper or plastics inside the driver when the insulation deteriorates. The overcurrent protection device (MCB) cannot trip as the current flowing through a driver circuitry even though there are overheating components could be rather normal and well under the rated tripping current of the MCB.

In addition, there is no way to trip the earth leakage protection device (ELCB) due to the lack of an earth wire connected to the LED tube.

The overheating may persist for a time unnoticed causing the materials to eventually catch fire. There is nothing to stop the fire which could spread out through electric cables or other plastic materials near by.

Advantages of using LED tube with remote driver.

1) Good heat dissipation

The remote driver has big enough space to house high quality and adequately rated components especially the electrolytic capacitors this ensure good heat dissipation. The life of the driver is greatly extended and without the risk of overheating. Proven experience shows life span of driver beyond 50,000 solid working hours is possible.

2) Better EMC performance

As more space is available inside the remote driver, use of higher grade filter circuit is possible thus ensuring higher performance in harmonic suppression and EMC.

3) Possible to apply different types of dimming and control

High quality dimming (step dim, Triac dim, 0-10V dim or DALI) and control can be incorporate to achieve Building Energy Code requirements as well as other functional requirements such as conference room dimming.